Understanding Heat Pump Systems in New Hampshire’s Climate

Heat pumps have become increasingly popular throughout Amherst and the surrounding New Hampshire communities, offering year-round comfort through both heating and cooling capabilities. These versatile systems work by transferring heat rather than generating it, making them significantly more energy-efficient than traditional heating methods. During winter months, heat pumps extract warmth from outdoor air—even when temperatures drop below freezing—and transfer it inside your home. In summer, the process reverses, removing heat from indoor spaces and releasing it outdoors. This dual functionality makes heat pumps particularly valuable in New Hampshire’s variable climate, where temperatures can range from below zero in winter to over 90 degrees in summer.

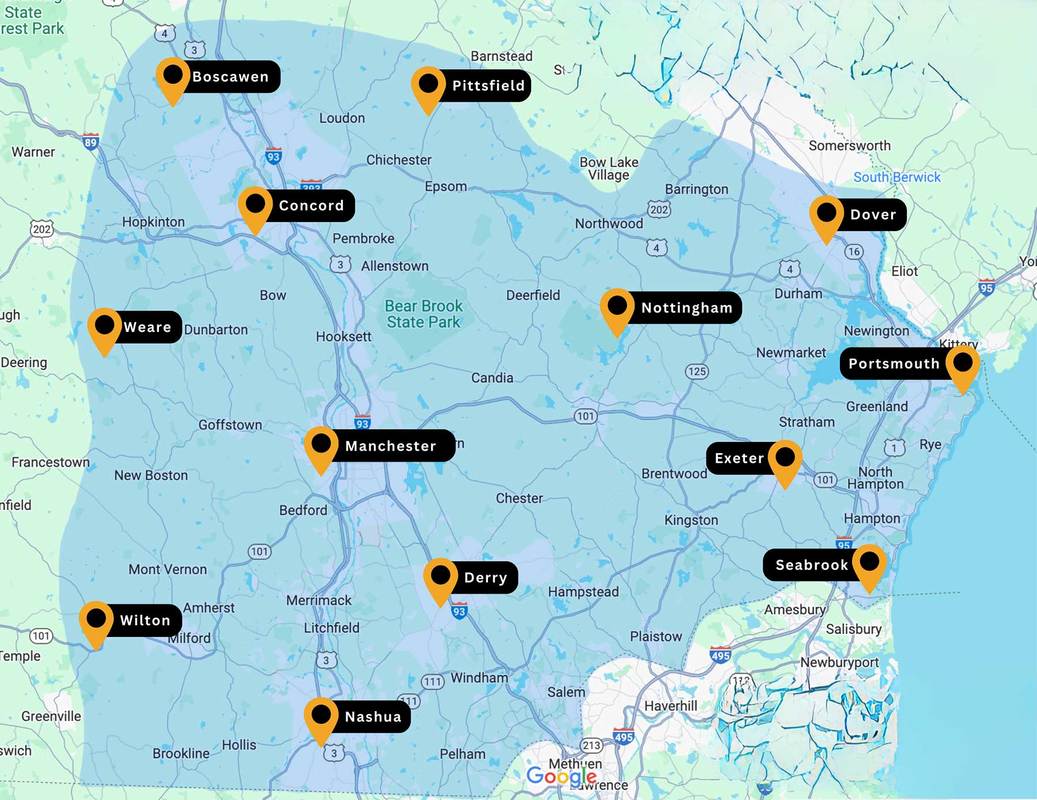

The technology behind modern heat pumps has advanced considerably over the past decade, with newer models capable of maintaining efficiency even in temperatures as low as negative 15 degrees Fahrenheit. This improvement has made heat pumps viable primary heating sources for homes throughout Amherst, where winter temperatures regularly dip below freezing. At Paul the Plumber, we’ve installed and maintained hundreds of heat pump systems across southern New Hampshire over our 22 years in business, giving us deep insight into how these systems perform in our specific climate conditions.

Critical Maintenance Tasks for Optimal Performance

Regular maintenance of your heat pump system involves several essential tasks that directly impact its efficiency, longevity, and reliability. Filter replacement or cleaning stands as the most fundamental maintenance requirement, with most systems needing attention every one to three months depending on usage patterns and environmental factors. Clogged or dirty filters force your system to work harder, reducing efficiency by up to 15% and potentially causing premature wear on components. Beyond filters, outdoor unit coils require periodic cleaning to remove debris, leaves, and dirt that accumulate naturally. Indoor coils also need attention, as dust and pet dander can build up over time, creating an insulating layer that reduces heat transfer efficiency.

Refrigerant levels require professional monitoring and adjustment, as even small leaks can significantly impact system performance. Our licensed technicians check refrigerant pressure during maintenance visits, looking for signs of leaks or inadequate charge levels. Electrical connections need regular inspection and tightening, as vibration during normal operation can cause connections to loosen over time, creating resistance that generates heat and poses potential safety hazards. We also inspect and clean condensate drains, which can become clogged with algae or debris, potentially causing water damage or system shutdowns. As a BBB accredited company with an A+ rating, we ensure every maintenance visit includes comprehensive system testing to verify proper operation across all modes and settings.

Seasonal Maintenance Requirements

Spring maintenance prepares your heat pump for cooling season demands, focusing on cleaning outdoor units that may have accumulated winter debris. We inspect fan blades for damage from ice or falling branches, check defrost cycles for proper operation, and verify that drainage systems function correctly. This is also an ideal time to test cooling performance before summer heat arrives, allowing time for any necessary repairs without emergency service calls. Our family-owned and operated business understands the importance of proactive maintenance, which is why we back all our work with a 2-year parts and labor warranty, extending to 3 years for our club members.

Fall maintenance emphasizes heating preparation, including thorough inspection of backup heating elements in systems equipped with auxiliary heat. We verify proper sequencing between heat pump and auxiliary heat operation, ensuring smooth transitions during extreme cold snaps. Thermostat calibration becomes particularly important before heating season, as even small inaccuracies can lead to comfort issues and increased energy consumption. Our technicians also inspect insulation on refrigerant lines, replacing any damaged sections that could reduce efficiency or cause condensation problems.

Common Issues and Prevention Strategies

Heat pumps in Amherst face specific challenges related to our climate and environmental conditions. Ice buildup on outdoor units during winter represents a common concern, though modern systems include defrost cycles to address this automatically. However, excessive ice accumulation may indicate problems with defrost controls, refrigerant levels, or airflow restrictions. Regular maintenance helps identify these issues before they cause system failures. Unusual noises often signal developing problems—squealing sounds may indicate belt issues in older units or bearing problems in fan motors, while rattling might suggest loose components or debris in the system.

Short cycling, where the system turns on and off frequently without completing full cycles, wastes energy and stresses components. This problem often stems from oversized equipment, thermostat issues, or refrigerant problems. Our experienced technicians diagnose the root cause rather than simply addressing symptoms, ensuring long-term solutions. With thousands of verified 5-star reviews across multiple platforms, our customers appreciate our thorough approach to problem-solving and commitment to treating every customer like family.

Professional Maintenance Benefits and Frequency

Professional maintenance provides benefits beyond what homeowners can accomplish independently. Our licensed and background-checked technicians possess specialized tools and expertise to detect problems before they become costly repairs. We perform comprehensive system diagnostics, measuring temperatures, pressures, and electrical values to ensure operation within manufacturer specifications. This detailed approach helps maintain manufacturer warranties, which often require documented professional maintenance.

- Energy efficiency optimization: Regular professional maintenance maintains peak efficiency, reducing energy costs by 10-25% compared to neglected systems

- Extended equipment lifespan: Properly maintained heat pumps typically last 15-20 years, versus 10-12 years for neglected units

- Improved indoor air quality: Clean filters and coils reduce allergens and improve air circulation throughout your home

- Preventive problem identification: Early detection of worn components prevents unexpected breakdowns during extreme weather

- Consistent comfort levels: Well-maintained systems provide more even temperatures and humidity control

Most manufacturers recommend professional maintenance twice annually, ideally in spring and fall. This schedule aligns with seasonal transitions, preparing systems for peak demand periods. Our upfront pricing ensures transparency, with no surprise charges after service completion. We believe in treating employees like family, which translates to superior service delivery—happy technicians provide better customer experiences, contributing to our reputation for service with a smile. Regular maintenance visits also provide opportunities to discuss system upgrades or efficiency improvements, helping homeowners make informed decisions about their HVAC investments. We’re always happy to help explain options and provide honest recommendations based on your specific needs and budget considerations, maintaining the integrity and reliability that have sustained our business for over two decades in the Amherst and greater Nashua area. Contact us today.