Heat Pump Maintenance Auburn, NH

Heat pumps have become increasingly popular in Auburn and throughout southern New Hampshire as homeowners seek energy-efficient solutions for year-round comfort. These versatile systems provide both heating and cooling, making them ideal for our region’s varied climate. At Paul the Plumber, we understand that proper maintenance is essential for keeping your heat pump operating at peak efficiency throughout its lifespan. Regular maintenance not only ensures consistent comfort but also helps prevent unexpected breakdowns and extends equipment life by several years.

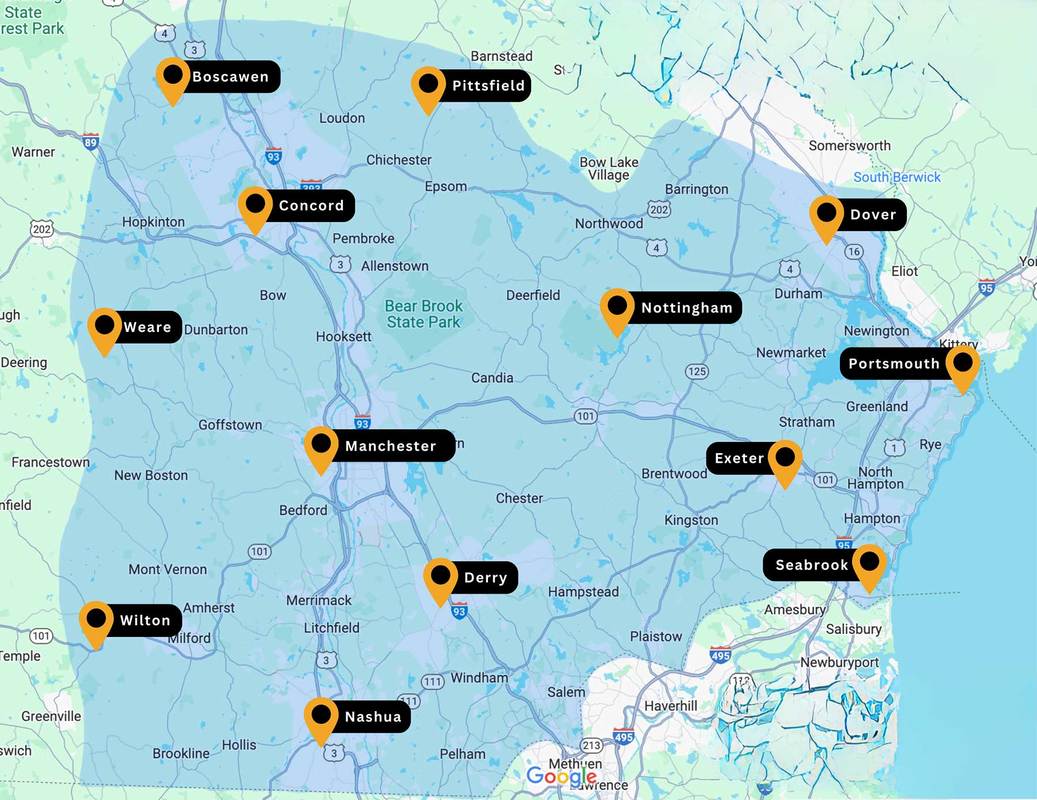

Our family-owned and operated company has been serving Auburn and surrounding communities for 22 years, developing deep expertise in heat pump technology and maintenance requirements specific to New Hampshire’s climate conditions. We’ve seen firsthand how proper maintenance can reduce energy consumption by up to 25% and prevent up to 95% of system failures. Our BBB accredited A+ rating reflects our commitment to delivering exceptional service with integrity and reliability that thousands of verified 5-star reviews across multiple platforms confirm.

Understanding Heat Pump Components and Operation

Heat pumps work by transferring heat between indoor and outdoor environments using refrigerant cycles, reversing valves, and specialized coils. During winter months, the system extracts heat from outdoor air—even when temperatures drop below freezing—and transfers it inside. In summer, the process reverses, removing heat from your home and releasing it outdoors. This heat transfer process relies on multiple components working in harmony, including the compressor, evaporator coil, condenser coil, expansion valve, and reversing valve.

The efficiency of this process depends heavily on clean components and proper refrigerant levels. Dust, debris, and normal wear affect heat transfer capabilities, forcing the system to work harder and consume more energy. Our licensed technicians understand these intricate systems and perform comprehensive maintenance that addresses each component’s specific needs. We treat customers like family, taking time to explain what we’re doing and why each maintenance task matters for your system’s performance and longevity.

Essential Maintenance Tasks and Frequency

Professional heat pump maintenance involves numerous critical tasks that require specialized knowledge and equipment. Filter replacement or cleaning should occur monthly during peak usage seasons, as clogged filters restrict airflow and force the system to work harder. Coil cleaning is essential twice yearly because dirty coils reduce heat transfer efficiency by up to 40%. Our technicians carefully clean both indoor and outdoor coils using specialized solutions that remove buildup without damaging delicate fins.

Refrigerant level checks ensure optimal heat transfer capacity, as both overcharging and undercharging reduce efficiency and can damage components. We verify electrical connections, test capacitors, inspect contactors, and measure amp draws to identify potential failures before they occur. Thermostat calibration ensures accurate temperature control, while lubricating motors and checking belt tension prevents premature wear. We also inspect and clean condensate drains to prevent water damage and maintain indoor air quality. All our work comes with a 2-year parts and labor warranty, with an option for 3-year coverage through our club membership program.

Seasonal Maintenance Considerations for Auburn Climate

Auburn’s climate presents unique challenges for heat pump systems, with humid summers and cold winters requiring different maintenance approaches. Spring maintenance focuses on preparing for cooling season by cleaning outdoor units that accumulated debris over winter, checking refrigerant levels before summer demand peaks, and ensuring drainage systems function properly for condensate removal. We verify that the reversing valve switches smoothly between heating and cooling modes and test cooling capacity to ensure comfortable temperatures during hot summer days.

Fall maintenance emphasizes heating preparation, including inspecting auxiliary heat strips that provide backup heating during extreme cold. We check defrost cycles that prevent ice buildup on outdoor coils during winter operation and ensure proper airflow for efficient heat distribution. Weather stripping and insulation around refrigerant lines receive attention to prevent energy loss. Our technicians, all licensed and background checked, understand how seasonal temperature swings affect system performance and adjust maintenance procedures accordingly.

Common Heat Pump Problems and Prevention

Many heat pump issues develop gradually and can be prevented through regular maintenance. Ice buildup on outdoor units often results from restricted airflow, low refrigerant, or defrost system malfunctions. Short cycling, where the system turns on and off frequently, typically indicates oversized equipment, thermostat problems, or refrigerant issues. Unusual noises might signal loose components, worn bearings, or debris in the system. Reduced heating or cooling capacity often stems from dirty filters, low refrigerant, or compressor problems.

- Frozen outdoor coils: prevented by maintaining proper refrigerant levels and ensuring defrost cycles function correctly

- Insufficient heating: avoided through regular coil cleaning and auxiliary heat strip inspection

- High energy bills: minimized by maintaining clean filters and optimal refrigerant charge

- Uneven temperatures: resolved by ensuring proper airflow and ductwork integrity

- System not switching modes: prevented by regular reversing valve maintenance

Professional Maintenance Benefits and Cost Savings

Investing in professional maintenance delivers substantial returns through energy savings, extended equipment life, and avoided repair costs. Studies show that properly maintained heat pumps consume 10-25% less energy than neglected systems, translating to hundreds of dollars in annual savings for Auburn homeowners. Regular maintenance extends system life from an average of 10-12 years to 15-20 years, delaying costly replacement expenses. Early problem detection during maintenance visits prevents minor issues from becoming major repairs that could cost thousands.

Indoor air quality improves significantly with regular maintenance, as clean filters and coils reduce allergens, dust, and mold growth. Manufacturer warranties often require professional maintenance documentation, protecting your investment. We offer service with a smile, providing upfront pricing so you always know costs before work begins. Our approach treats employees like family too, ensuring motivated technicians who genuinely care about your comfort and satisfaction. We’re happy to help you establish a maintenance schedule that fits your budget while maximizing system performance and reliability throughout Auburn’s demanding seasons. Contact us today.